2i Digital Photometer

The most advanced, innovative and user friendly digital aerosol photometer available today, the 2i Digital Photometer is portable, yet rugged, and the ideal instrument for in-situ filtration system integrity testing. The iProbe, a handheld scanner with local LCD display and controls, enables the operator to change settings without stopping to adjust the base unit, minimizing downtime.

Applications

-

Independent Filter Certifiers;

-

Nuclear Facilities;

-

Pharmaceutical Manufacturers;

-

Medical Facilities & Cleanrooms;

-

Bio-Safety Cabinets & Fume Hoods.

Key Features & Benefits

-

Lightweight, portable and rugged;

-

Large 4.3″ LCD;

-

iProbe;

-

User settable aerosol noise suppression for more stable aerosol measurements;

-

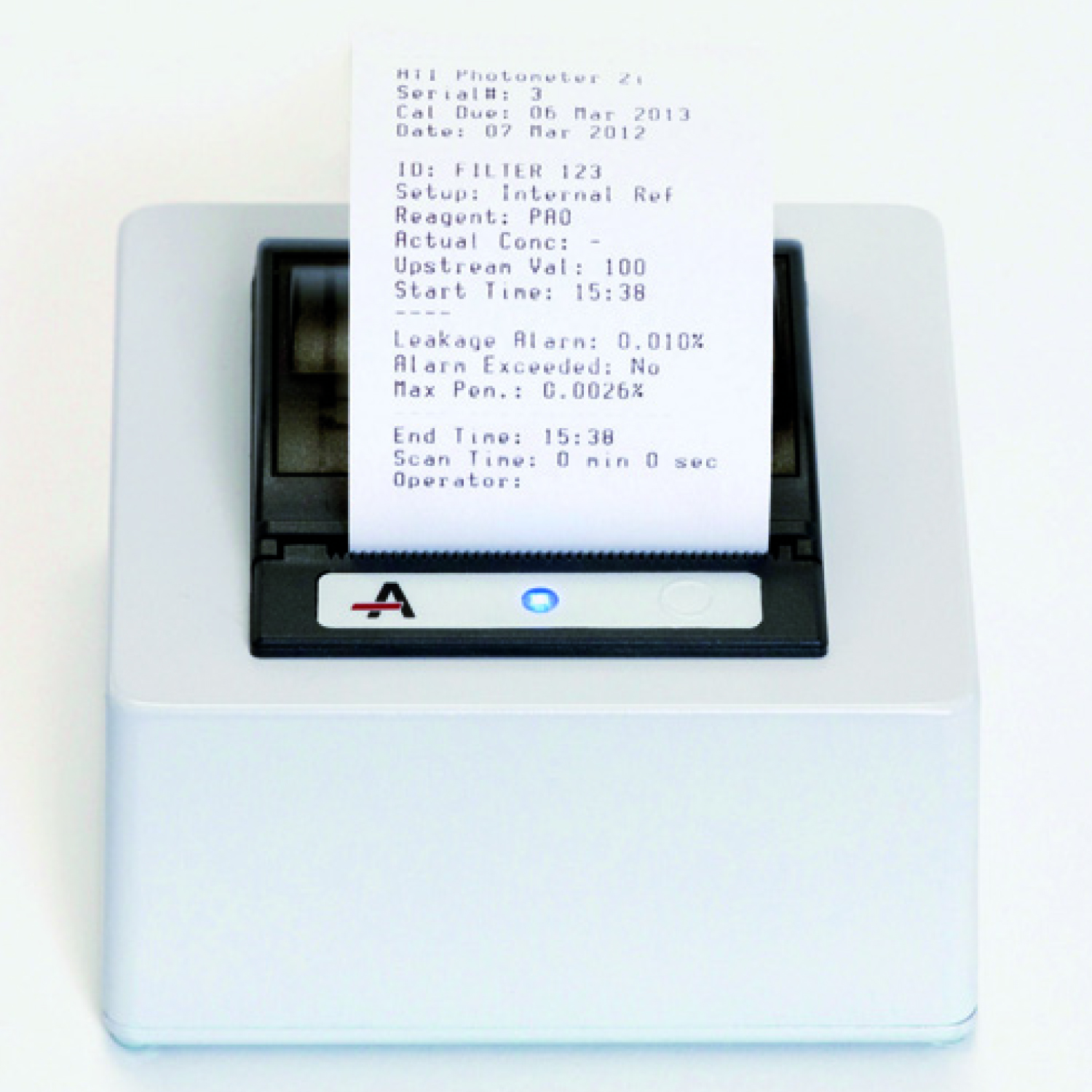

Printer (optional) available for reporting;

-

2i-N models include a sealed sample train, allowing for the safe removal and replacement of contaminated sampling components.

Innovative User Interface

The 2i base instrument’s 4.3” LCD gives life to the easy to use, menu driven interface. Aerosol measurements and pump sampling rates are prominently displayed for easy viewing. System parameters and selections such as alarm types, alarm set points and aerosol reagent are shown on the lower menu bar, while icons at the top of the screen give the status of connected peripherals, reporting functions, and aerosol noise suppression selections.

Data Reporting

Three unique report functions are now available with the 2i through the USB or optional thermal printer interface. Continuous mode offers the same output as ATI’s legacy photometers to ensure backward compatibility. Monitoring mode provides the ability to collect data at user defined intervals for long term sampling. Summary mode, which gives discrete reporting capability for individual filter locations, can output to the thermal printer to meet customer documentation requirements.

iProbe

The iProbe with a 12ft cable acts as an extension of the base instrument through a nearly identical user interface. All status and selection icons from the base unit are represented on the iProbe. With the press of a button, the sampling location can be remotely selected and switched by way of an electronically controlled valving system.

Performance Guaranteed

To ensure consistent results in all applications and altitudes, the sampling flow rate is constantly monitored and controlled via a pulse width modulated pump. The 2i has been independently tested and qualified to ensure compliance with all applicable electrical and safety requirements.

Hazardous Environments

Designed for the rigors of nuclear and other hazardous applications, the 2i-N (the nuclear version of the 2i) is equipped with a unique, sealed sample train. The unit is engineered to allow safe removal and replacement of contaminated sampling components.

Simple maintenance

Annual NIST traceable calibration service is provided by ATI or an ATI-certified calibration facility. Calibration includes setting the aerosol reagent references, sample flow reference points, operating voltages, and servicing the light scattering chamber assembly. Routine preventative maintenance entails cleaning and inspection of internal sample tubing and connections, the internal reference filter, and iProbe.

Enhanced Features

Upstream aerosol mass concentrations are displayed in actual mass concentration values of micrograms per liter (μg/l). User settable Aerosol Noise Suppression (ANS) allows for more stable aerosol.

| PHOTOMETER CHARACTERISTICS | |

| Dimension (L x W x H) | 25.7 см x 33 см x 15.2 см |

| Weight | 8.6 кг; 21.8 кг |

| Power | 100 to 250 Volts AC, 50/60Hz automatic adjustment 0.5 amps @ 120V, 0.25 amps @ 240V |

| Auto Zero | Automatically establishes zero reading at startup |

| Alarm | User selectable audible, visual, and vibratory alarms notify the user when the user defined set point is exceeded |

| Flow Control | Pulse Width Modulation (PWM) control ensures sampling rate of 1 cfm (28.3 Lpm) +/- 10% in all applications. |

| Reagent Settings | PAO-4, DOP, Ondina, PEG, Krydol, Corn Oil, Mineral Oil, Paraffin |

| Dynamic Range | 0.1 μg/m3 ... 120 mg/m3 |

| Sensitivity | 1% of readings> 0.01% ... 100% |

| Repeatability | 0.5% of readings> 0.01 % ... 100% |

| Light Source | Solid State, rated for life of instrument |

| Output | USB Connection |

| Reporting | Continuous, Summary, and Monitoring modes |

| Printer Accessory | Thermal Printer for hard copy of Summary Report |

| Standards Compliance | NSF 49, IEST, ISO-14644 CE, FCC, EN61010-1:2010, EN61326-1 :2006 |