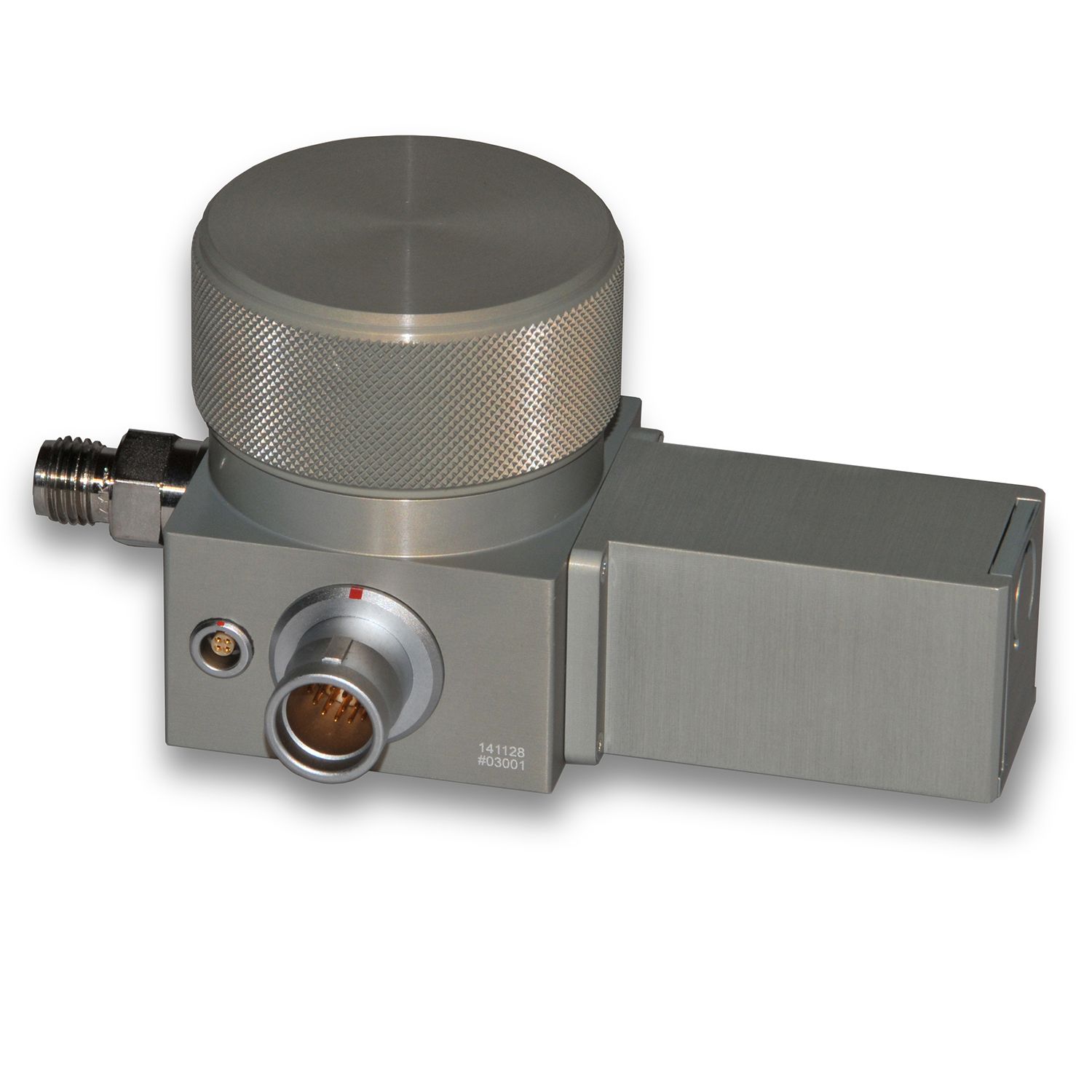

Precision dew point hygrometer for high temperatures MBW 473-SHX

The SHX measuring head is an evolution of the tried and tested SH measuring head. It is able to operate in test conditions up to +125 °C thanks to the use of optical components, electronics and materials that are able to withstand high temperatures.

The SHX measuring head is an evolution of the tried and tested SH measuring head. It is able to operate in test conditions up to +125 °C thanks to the use of optical components, electronics and materials that are able to withstand high temperatures. Our development team tested a range of components over the SHX working range to achieve the best possible performance. By comparison with our state-of-the-art 373 reference hygrometer, we were able to verify that the performance meets or exceeds the specifications.

Modular design

The key components of the SHX such as the optical module and fan assembly can be easily replaced by the user without the need for system re-calibration.

Sample flow control at high temperature

Precise dew point measurement depends on controlled and stable gas flow over the dew point mirror and known pressure. Flow rate is especially critical at high temperature and humidity conditions. The SHX measuring head incorporates a sample fan with user controllable speed that maintains a stable flow within the recommended range of 0.3 … 1 litre per minute at atmospheric pressure. A high temperature motor is combined with a micro engineered aluminium impeller/cowl combination to maintain reliable and stable sample flow. Flow rate can be changed through the 473 front panel user interface or by serial commands.

Features:

-

Precise and stable chilled mirror dew point mirror technology;

-

Precise and stable chilled mirror dew point mirror technology;

-

High temperature optical components;

-

High temperature sample fan;

-

Cable mounted dew point measuring head;

-

Barometric pressure measurement option;

-

Intuitive color touch screen user interface;

-

Integral calibration stability verification.

Typical applications:

-

Validation of climatic chambers;

-

Climatic chamber calibration;

-

HALT/HASS test chambers;

-

Fuel cell test;

-

Dryer performance.